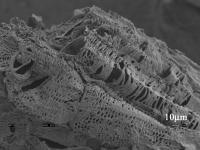

A magnified image of a cornstalk particle shows the many tiny pores that pretreatment -- a phase of the ethanol production process -- opens up. These pores create more surface area for subsequent reactions to take place and give enzymes better access to cellulose, the source for cellulosic ethanol. Researchers said this information could help in establishing an economic method for industrial production of cellulosic ethanol. Credit: Purdue University photo/Meijuan Zeng Tiny pores within plant cells may hold promise for green fuels.

Researchers have discovered that particles from cornstalks undergo previously unknown structural changes when processed to produce ethanol, an insight they said will help establish a viable method for large-scale production of ethanol from plant matter.

Their research demonstrates that pretreating corn plant tissue with hot water - an accepted practice that increases ethanol yields 3 to 4 times - works by exposing minute pores of the plant's cell walls, thus increasing surface area for additional reactions that help break down the cell wall.

"This brings together the tools that link the processing technology to the plant tissue physiology," said Nathan Mosier, an assistant professor of agricultural and biological engineering at Purdue University. "It helps us understand, on a fundamental level, what the processing is doing and how we can improve it."

Mosier said that research, further described in a study published Thursday (April 26) in the journal Biotechnology and Bioengineering, applies to cellulosic ethanol, or ethanol produced from cellulose, which is a key component of plant's cell walls.

Using high-resolution imaging and chemical analyses, the researchers determined that pretreatment opens reactive areas within the cells of the corn stover - another name for postharvest corn remnants, like leaves and stalks - that were previously overlooked. In the next step of processing, these enlarged pores are more easily attacked by enzymes that convert cellulose into glucose, which is in turn fermented into ethanol by yeast, Mosier said.

Producing ethanol from cellulose would be advantageous over existing industrial processes in several ways, said Michael Ladisch, the study's co-author and a professor of agricultural and biological engineering.

Currently, almost all industrial ethanol derives from either starch found in corn grain or from sugar cane. This limits U.S. ethanol production, which is almost entirely from corn grain, to a grain supply that already is in demand for a variety of uses.

"Cellulosic ethanol would allow industry to expand beyond the limits brought about by corn's other uses, like sweetener production, animal feed and grain exports," Ladisch said.

For these reasons, he said, cellulosic ethanol also would likely put less pressure on food prices.

The new process has the potential to become more efficient, with a larger potential supply of plants that can be grown more economically than traditional row crops. What's more, research in plant science has yielded - and will likely continue to yield - new types of energy crops with larger pools of usable cellulose.

However, the catch is that cellulose is not easily freed from the cell wall's complex, rigid structure, and, to date, cellulosic ethanol has not been commercially viable. Ladisch said this study should help change that.

"This study will help us translate science from the lab to an industrial setting and will help produce cellulosic ethanol economically," he said.

Plant's cell walls are rigid structures made up of a variety of polymers, including cellulose and hemicellulose, which can be converted into sugars that are then made into ethanol. However, cellulose and hemicellulose are held in place by a variety of compounds like lignin, a strong cellular glue that resists treatment and protects cellulose from being broken down. Mosier and Ladisch found that after pretreatment opens corn's tiny pores, enzymes not only removed more cellulose and hemicellulose from the cell wall, but also removed it at a faster rate.

Cellulosic ethanol comes from plant biomass, another term for the tissue of recently dead plants, or plants that grow and die annually. This distinguishes the current supply of plant biomass - to be used for cellulosic ethanol - from plant matter that died eons ago and through time created our current supply of carbon fuels, namely coal and oil. This is why plant biomass is often labeled as renewable, since it can be grown each year, and why petroleum is referred to as non-renewable - once it's gone, it cannot be replaced.

Mosier and Ladisch are currently at work on a variety of projects related to ethanol production, such as how to best scale up from laboratory operations.

They have conducted research in this area for years. The hot liquid water pretreatment process used in this study was originally developed in the Laboratory of Renewable Resources Engineering at Purdue, which Ladisch directs.

Source : Purdue University

Print Article

Print Article Mail to a Friend

Mail to a Friend